TL;DR: Paint preparation in auto collision repair is a meticulous process crucial for high-quality finishes. Timing is vital, as factors like damage complexity, contamination removal, rust prevention, and paint type influence duration. Optimizing scheduling around these timelines enhances customer satisfaction by minimizing downtime, maximizing productivity, and improving resource allocation in automotive workshops.

In the realm of property maintenance, meticulous paint preparation is a cornerstone of successful repairs. This article delves into the intricate timing dynamics of paint preparation and its profound impact on repair scheduling. We explore why understanding this process is paramount for efficient project management. From assessing surface conditions to choosing appropriate primers, each step influences the duration. By deciphering these factors, professionals can optimize timelines, ensuring repairs are completed swiftly and effectively, ultimately enhancing customer satisfaction.

- Understanding Paint Preparation: The Foundation for Successful Repairs

- Timing is Crucial: Factors Influencing Paint Preparation Duration

- Optimizing Repair Scheduling: Aligning with Paint Preparation Timelines

Understanding Paint Preparation: The Foundation for Successful Repairs

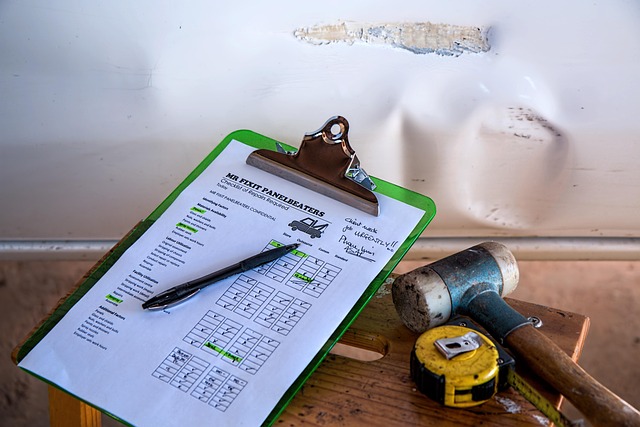

Understanding Paint preparation is the foundation for successful repairs at any auto collision center. It’s a meticulous process that involves several steps, from surface cleaning and decontaminating to sanding and priming, ensuring the perfect base for new paint. This crucial stage directly impacts the quality of the final finish and the longevity of the repair work.

Efficient paint preparation timing plays a vital role in scheduling repairs. Optimizing this process allows auto body work and even auto glass replacement to be completed faster, reducing downtime for customers. In an automotive body shop, effective planning ensures that every step, from initial assessment to final touch-ups, is executed with precision, resulting in a superior job well done.

Timing is Crucial: Factors Influencing Paint Preparation Duration

Timing is Crucial: Factors Influencing Paint Preparation Duration

In the realm of automotive collision repair and car body repair, paint preparation is a meticulous process that significantly impacts the overall repair scheduling. The duration required for this step varies based on several factors, each playing a crucial role in determining the final outcome. One of the primary considerations is the extent of the dent removal process—whether it involves simple creases or complex structural damage. Complex dents often necessitate more time for meticulous correction and preparation before painting can commence.

Additionally, the paint preparation timeline is influenced by surface contamination, rust prevention measures, and the type of paint used. Contaminants like grease, dirt, or old paint need to be thoroughly removed to ensure a seamless finish. Rust prevention treatments, while essential for long-lasting repairs, also add time to the process. Lastly, different paints have varying drying and curing times, which must be factored into the overall schedule for dent removal and automotive collision repair to proceed smoothly.

Optimizing Repair Scheduling: Aligning with Paint Preparation Timelines

In the realm of automotive aesthetics and repairs, optimizing scheduling plays a pivotal role in ensuring customer satisfaction and efficient workshop operations. Aligning vehicle repair processes with paint preparation timelines is a game-changer for workshops, significantly impacting overall productivity. By understanding the intricacies of paint preparation—its duration, complexities, and potential delays—auto body repair specialists can meticulously plan and schedule other related tasks, such as dent repair or auto painting.

This strategic alignment ensures that when paint is ready, all necessary repairs are completed, minimizing wait times for customers and maximizing workshop efficiency. Efficient scheduling not only reduces the overall turnaround time but also allows for better resource allocation. For instance, if a vehicle requires extensive dent repair before painting, adjusting the schedule to accommodate this can prevent delays caused by waiting for paint preparation, ultimately leading to a smoother, more satisfying customer experience.

In conclusion, optimal repair scheduling hinges on efficient paint preparation. By understanding the factors influencing preparation duration and aligning timelines accordingly, professionals can streamline processes, reduce delays, and ensure superior repair outcomes. This strategic approach to paint preparation not only enhances project efficiency but also contributes to client satisfaction in the long run.