The paint preparation landscape is rapidly evolving due to technological advancements and demand for high-quality finishes in luxury vehicle repair and automotive collision sectors. Innovative techniques, automated systems, eco-friendly low-VOC paints, digital technologies, and sustainable materials are driving efficiency, aesthetics, and quality improvements. These transformations meet industry standards, consumer expectations, and environmental regulations while enhancing communication, project management, and transparency.

The ever-evolving landscape of paint preparation technologies and materials is reshaping industries worldwide. As we look ahead, several trends emerge, promising enhanced efficiency, sustainability, and performance. This article explores key advancements in surface preparation for improved paint adhesion, the rise of eco-friendly solutions, and the integration of digital technologies to streamline paint application prep. Discover how these innovations are revolutionizing the way we approach paint preparation.

- Evolving Techniques in Surface Preparation for Paint Adhesion

- Eco-Friendly Materials and Solutions Reshaping Paint Preparation

- Digital Integration: Enhancing Efficiency in Paint Application Prep

Evolving Techniques in Surface Preparation for Paint Adhesion

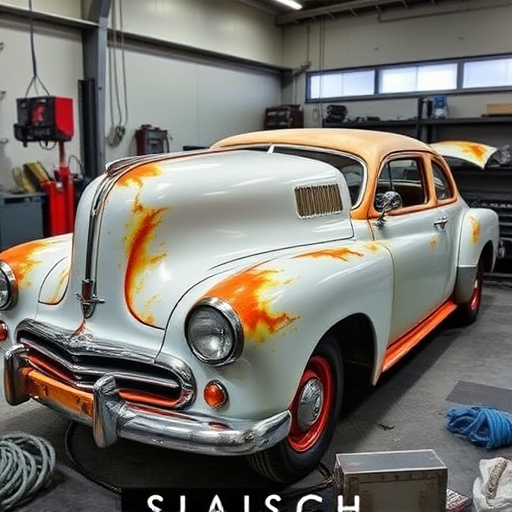

The landscape of paint preparation is undergoing a metamorphosis, driven by advancements in technology and the ever-increasing demand for superior finishes in various industries, notably luxury vehicle repair and automotive collision repair. Traditional methods are being replaced by innovative techniques that not only enhance paint adhesion but also streamline the entire process. For instance, automated surface conditioning systems are gaining traction, offering precise control and efficiency compared to manual methods. These systems use advanced technology to ensure a consistent and thorough clean, preparing surfaces for paint applications in bumper repair scenarios and beyond.

Furthermore, the integration of new materials and coatings is playing a pivotal role. Specialized primers and undercoats designed for specific substrates are now available, ensuring optimal adhesion even on challenging surfaces. This evolution in paint preparation technologies promises not just improved aesthetics but also enhanced durability in automotive repairs, setting new standards in both quality and efficiency.

Eco-Friendly Materials and Solutions Reshaping Paint Preparation

In recent years, the paint preparation industry has witnessed a significant shift towards eco-friendly materials and solutions, driven by both consumer demand and regulatory pressures. This trend is reshaping how auto body services and collision repair centers approach their work, moving away from traditional chemical-intensive processes. One of the key areas of focus is the development of low-VOC (volatile organic compound) paints and coatings, which not only reduce air pollution but also create a healthier working environment for technicians in car paint services.

Additionally, the integration of sustainable materials, such as recycled content and bio-based resins, has become increasingly prevalent. These innovations not only minimize environmental impact but also offer performance advantages, including improved durability and better adhesion. As these trends continue to evolve, collision repair centers are embracing more efficient and responsible methods in paint preparation, ensuring they stay at the forefront of both industry standards and consumer expectations.

Digital Integration: Enhancing Efficiency in Paint Application Prep

The integration of digital technologies is transforming the landscape of paint preparation, making processes more efficient and precise. From advanced software to AI-driven tools, these innovations are revolutionizing how professionals approach car dent removal and autobody repairs. Digital solutions offer accurate measurements and real-time data, ensuring every step of the paint application prep is optimized. For instance, 3D scanning technology can quickly capture vehicle surfaces, eliminating manual measuring errors often associated with traditional methods.

This digital shift also streamlines communication between technicians and customers, especially after a fender bender. Digital platforms enable before-and-after comparisons, providing clients with transparent visuals of the repair process. Furthermore, cloud-based systems allow for efficient project management, ensuring every detail related to paint preparation is accessible and well-organized, ultimately leading to faster turnaround times and higher customer satisfaction.

As we look towards the future, paint preparation technologies and materials are undergoing a significant evolution. From advanced surface preparation techniques for improved adhesion to eco-friendly solutions reducing environmental impact, digital integration promises enhanced efficiency and precision. These trends not only benefit the painting industry but also contribute to a more sustainable and intelligent future. By adopting these innovations, professionals can ensure superior paint jobs while minimizing their ecological footprint.